Soil Washing in Canada

Soil washing is an ex-situ remediation technique used to physically remove contaminants from soil.

In Canada, soil washing is primarily used as a way to reduce the volume of soil that needs to undergo a secondary treatment or disposal. The process efficiently extracts metals, hydrocarbons, salt, pesticides, and other contaminants from the bulk input material and allows for the recovery of clean aggregates like sand and gravel for reuse.

- Reduces soil disposal costs by up to 70%, minimizing landfill fees.

- Separates heavy metals, hydrocarbons, salt and solvents from soil.

- Closed loop system allows for reuse up to 95% of water, reducing environmental impact.

- Recovers clean sand, gravel and aggregates for reuse.

- Customizable and adaptable process for industrial, minin, and urban brownfield sites.

- Faster than bioremediation or natural attenuation, with treatment cycles ranging from hours to days.

- Meets Canadian environmental standards for excess soil reuse and remediation.

- Scalable systems are custom-built for mobile or fixed treatment facilities.

- Reduced effectiveness in high clay content soils.

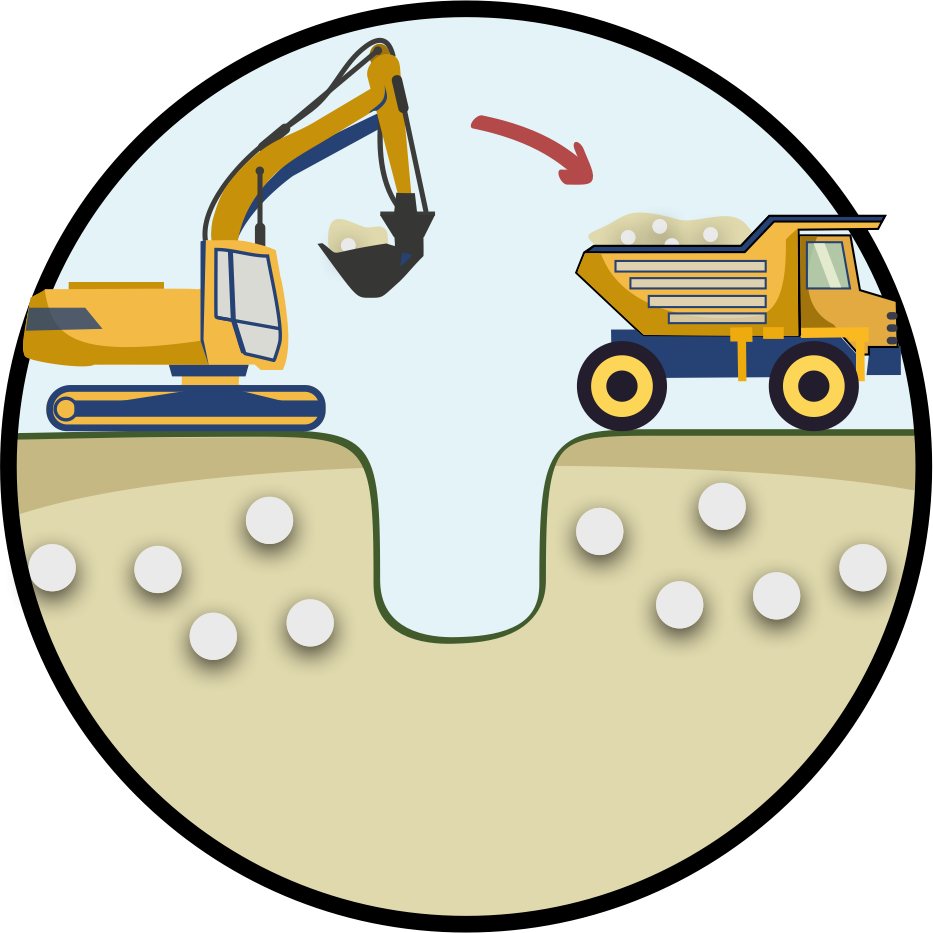

- Soil washing is an ex-situ process, meaning soil must be excavated before it can be processes.

- Northern regions have shorter operational season unless mitigation steps are taken to prevent process water from freezing.

- Requires proper handling of contaminant-rich sludge and filter cake.

- Wash water must be treated and recycled to avoid excess liquid waste.

- Not ideal for certain organic contaminants (ex.: pesticides, dioxins, and PCBs).

- Sandy & loamy soils: Highly effective.

- Gravelly & aggregated soils: Suitable when contaminants are attached to fine particles.

- Silts & fine-grained soils: Requires additional attrition scrubbing and hydrocyclone separation.

- Clay-rich soils: Generates a larger quantity of contaminant-rich sludge with slower dewatering times and higher polymer loading.

- Mining waste & tailings: Effective for separating arsenic, lead, and heavy metals from industrial sites.

- Salt-impacted soils: Effective for separating salt from soils, may need additional water treatment steps and secondary leaching to remove residual salinity.

- Industrial & Urban fill: Removes hydrocarbons, solvents, and metals from contaminated construction materials.

- Capable of processing 0.1mm – 50mm particle sizes with proper screening and hydrocyclones.

- Scalable from 20 to 200 tonnes per hour, depending on site needs.

- Systems recover 80-95% of process water.

- Removes up to 99% of heavy metals, salts and hydrocarbons from larger size fractions.

- Uses grizzly screens, attrition scrubbers, hydrocyclones, dewatering presses, and chemical treatment.

- Contaminant-rich sludge can be treated via geotube dewatering, filter presses, or solidification.

- Can be combined with bioremediation, advanced oxidation, and soil stabilization.

How do we “wash” soil?

- Excavation & pre-treatment to remove debris and large particles.

- Washing & scrubbing where soil is vigorously mixed with washing fluids (water, surfactants, and chemical binders if required) to detach contaminants.

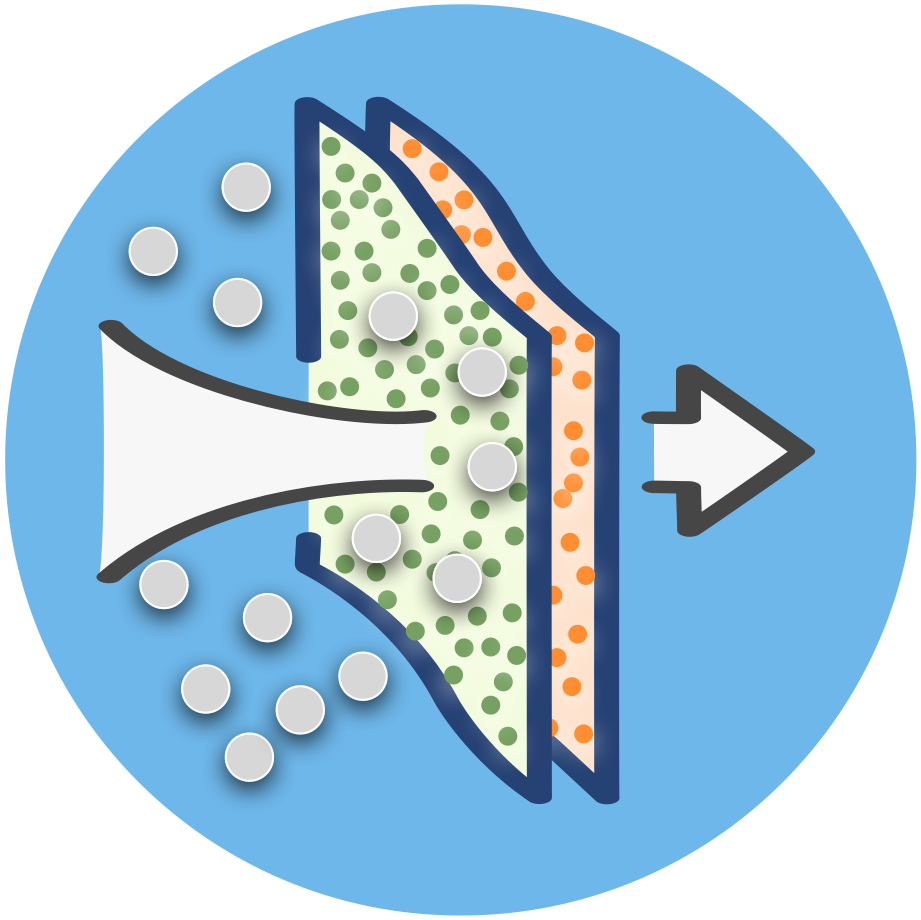

- Filtration & sifting where clean soil is separated from process water.

- Dewatering & sedimentation where residual fines are concentrated for proper disposal.

- Water treatment & recycling where contaminated wash water is treated using coagulation, dedmentaion, and filtration to allow up to 95% water reuse.

Custom Design Considerations

At Remea Canada, we custom-engineer each soil washing system to match site-specific geology and contamination levels.

This ensures we minimize the possible bottlenecks that can result from un-necessary components and also reduces the mobilization costs of each system.

On-site remediation vs centralized facilities

MOBILE UNIT

Ideal for large-scale contaminated sites where transporting soil to an off-site facility would be complex, costly or impractical.

- Industrial sites (lagoons, drilling operations, …)

- Oil & gas projects (hydrocarbons, solvents, salt, …)

- Infrastructure & construction projects (roads, railway, tunnels, …)

- Isolated or Northern sites (ex.: Giant Mine, Faro Mine, …)

FIXED FACILITY

Ideal for sites with continuous generation to ensure long-term cost savings.

- Municipal excess soils management sites

- Ports, transfer stations (ex.: dredging zones)

- High value clients (ex.: mining zones)

STRATEGY for Canada?

BOTH: Centralized + Mobile

- For large, one-time remediation projects, on-site soil washing is the preferred method.

- For municipal excess soil and ongoing remediation needs, fixed facilities provide cost stability and regulatory compliance.

- The ideal soil washing approach depends on contamination type, volume, and regional logistics.

Featured Case Study: Tented Mobile Facility

Remea brings two decades of global soil remediation experience, having delivered successful soil washing projects across europe.

France: Soil Washing Hydrocarbon Soils

- Date: May 2017 to December 2019

- Contaminants: Diesel, gasoline, chlorinated solvents.

- Soil Type: 75% of particle size >1 mm, 20% between 100 µm and 1 mm.

- Volume: 150 000 m3 of soil.

- Solution: On-site washing (3 size fractions) under tent.

- Outcome: 95% reuse of treated material.

Featured Case Study: Outdoor Industrial Lagoon

Poland: Soil Washing + Thermal

- Date: Jan 2019 to Sep 2021

- Contaminants: BTEX, Phenol, PAH

- Soil Type: Dredged sludge from bottom of pond

- Volume:

- Solution: Washed Sludge + Reburn of Extracted Vapours + Bioremediation of Pond

- Outcome:

Why Choose Washing over Disposal

REDUCE VOLUME

The purpose of soil washing is to concentrate the contaminants into a smaller fraction (soil or water). This fraction either undergoes secondary treatment or is disposed.

RECYCLING MATERIALS

The process does physically extract the target compounds. This means its possible repurpose or even purify these compounds for re-sell.

ON-SITE PROCESSING

No matter where in Canada, soil washing units can be mobilized to location. This is especially important when working in remote locations, when landfills are distant.

Frequently asked questions (FAQs)

Per- and polyfluoroalkyl substances (PFAS) exhibit unique behaviors during soil washing processes, influenced by their chemical properties and soil characteristics.

PFAS Characteristics and Soil Interaction:

- PFAS compounds are both hydrophobic (water-repelling) and lipophobic (fat-repelling), leading to complex interactions with soil components.

- The length of the carbon-fluorine chain in PFAS molecules affects their behavior. Longer-chain PFAS tend to adhere more strongly to soil particles, especially those rich in organic matter, due to increased hydrophobic interactions. Conversely, shorter-chain PFAS are less likely to bind tightly and are more prone to remain in the liquid phase during soil washing.

- When addressing PFAS-contaminated soils, soil washing can serve as a remediation strategy with specific objectives and challenges.

Challenges when washing PFAS

Objective:

Soil washing, in the context of PFAS contamination, will either be used to concentrate the contaminated soil into a smaller volume, or to transfer them into the washing water (source). This approach facilitates more efficient and cost-effective subsequent treatment or disposal. By isolating the PFAS-laden soil fraction, the overall volume requiring specialized handling is reduced, thereby optimizing resource utilization.

Behaviour:

During the soil washing process, PFAS compounds can partition into the process water, leading to secondary contamination. This necessitates effective management strategies to address the contaminated effluent.

Mitigation Strategies

To manage PFAS-contaminated process water resulting from soil washing, several treatment technologies can be employed:

- Granular Activated Carbon (GAC) to absorb PFAS in the process water (example).

- Ion exchange resins that can capture PFAS ions from the water (alternative or complementary to GAC).

- Foam fractionation technique that leverages the surfactant properties of PFAS, making use of air bubbles to concentrate PFAS.

- Advance Oxidation Processes (AOPs) to generate reactive species that can degrade PFAS molecules.

Implementing these strategies requires careful consideration of the specific PFAS compounds present, the characteristics of the process water, and the desired treatment outcomes. Combining multiple treatment methods may enhance overall effectiveness, ensuring that both the soil and water components of the remediation process are addressed comprehensively.

Soil washing is a proven ex-situ remediation technique designed to separate and remove pollutants from contaminated soil using physical, chemical, and hydrodynamic processes. It is particularly effective for heavy metals, petroleum hydrocarbons, salts, and industrial pollutants that are bound to fine soil particles or dissolved in pore water.

By leveraging hydrocyclone separation, attrition scrubbing, and chemical extraction, soil washing ensures that clean soil fractions can be recovered and reused, reducing reliance on landfilling and promoting sustainable remediation.

| Contaminant | Applicability |

|---|---|

| Aliphatic chlorinated hydrocarbons | Applies |

| Chlorobenzenes | Applies |

| Explosives | Applies |

| Metals | Applies |

| Monocyclic aromatic hydrocarbons | Applies |

| Non metalic inorganic compounds | Applies |

| Pesticides | Applies |

| Petroleum hydrocarbons (F1-F4) | Applies |

| Phenolic compounds | Applies |

| Polycyclic aromatic hydrocarbons (PAH) | Applies |

| Polychlorinated biphenyls (PCBs) | Applies |

Why Soil Washing Works for These Contaminants:

- Heavy Metals – Attach to fine particles and can be isolated using chemical separation and hydrocyclones.

- Hydrocarbons & Solvents – Removed using surfactants that break down oil films and aggressive mixing via attrition scrubbers.

- Salts & Deicing Contaminants – Dissolve in wash water and can be extracted using water treatment.